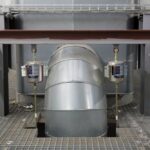

Expansion Bellows

World Class Expansion Joints supplier in India Expansion joints are used in piping systems to absorb thermal expansion or terminal movement where the use of expansion loops is undesirable or impractical. Metallic Expansion Joints are installed in pipe work and duct systems to prevent damage caused by thermal growth, vibration, pressure thrust and other mechanical forces.

There is a wide range of metallic bellows designs in a variety of materials. Options range from the simplest convoluted bellows used in petroleum refineries.Materials include all types of stainless steels, inconel and high grade nickel alloy steels.

We are the leading expansion bellows supplier in India and has now become a globally accepted provider of flexible piping systems exporting to more than 40 countries with a wide installation base covering almost all industrial sectors including and diverse as nuclear power and space programs.

Our adherence to the highest standards of quality and precision makes us experts and credible expansion joint manufacturer in India in Flexible Piping Systems. Supporting this dedication to quality is our ISO-9001 certified system for designing, manufacturing, and testing armed and equipped with the latest state-of-the-art technology.

The majority of our Expansion Bellows products are customized solutions. It means that we design and produce high temperature expansion joints or metal expansion joints in accordance with close interaction with the customer requirements. Furthermore, we are often involved with our customers in the design and development of new products for challenging applications.

All major industrialized manufacturing processes that require piping and changes in temperature trust upon our high temperature expansion joints and bellows products and services, Petro Chemical, Power generation, Fuel Cell Power Systems, Electrical Distribution Market, Industrial Gases, Chemical Processing, Oil and Gas Distribution, Utility piping, Solar Technology, Steel, Cement, Shipbuilding to name a few.

Spring Supports In Piping

To prevent constraints in the system, thermal expansion in the piping and the other piping components must not be hindered. The piping must therefore be supported in a correspondingly elastic manner so to compensate slight vertical displacements in the piping, Spring components are used as supports.

Pipework and/or vessels subject to temperature change or subsidence, etc. which give rise to vertical displacements should be supported by a resilient device which will absorb/accommodate the movement. For relatively small displacements (up to about 75mm) the variable spring support is recommended.

These components work on the basis of pre-set helical coil springs which exert a variable supporting load over the range of movement in accordance with their specified spring characteristics. Load variations resulting from this are limited through the stress analysis calculations, depending on the sensitivity of the piping.

Standard ranges of variable spring supports are produced in four basic travel ranges; 35mm, 70mm, 140mm and 210mm. The travels stated are the maximum working range of the springs. This full travel can be used providing the necessary calculations are carried out to ensure that the connecting equipment and pipework can withstand the large load changes that occur during pipe movement.

Most national standards do limit the load variation to maximum of 25%. It is therefore usual to select variable spring supports on this basis.